Supporting Our Customers Is A Key Priority.

IMTS Is Quickly Coming

For those who have been following the Memmelaar’s over the last 65 years of Royal Master Grinders my father and I are both into cars. We both work on and Drive Pre 1915 cars, sometimes more work on more than drive. My daughter Ava was hanging out with me in the garage and we were talking the other night and she asked why I didn’t have a home office in the house like her friends dad. She also asked why that when I do work at home at night I set my laptop up on my workbench in the garage. I have to say I was stumped. I took a photo and sent it to a friend of mine, he saw nothing odd that I would do something like this. The more I thought about it the more I realized that my dad and I still love to get our hands into projects, we both call it simply “digging in”. John Sr will still be in Royal Master’s shop working on a machine, adding his expertise to a project because there is not much he has not seen in his many years at Royal.

The parking lot was quite a scene today at Royal Master as Alex, Ryan and myself had two machines plus our booth and our skid of support materials out in the parking lot. At one point the FEDEX guy had trouble reaching our loading dock. We are to that point in the show cycle that we are seeing the finish line with a number of projects and just seeing the midpoints of others. Its crunch time. I break the show cycle into thirds. The first third is the hardest, the show prep. This starts in January, and ends in our case August 27th when the shipment is picked up.

The next third is the set-up at McCormick place and the actual show. This part of the process is the most fun for me as I get to look at everything that our team accomplished, the customers reactions and the sales generated. I enjoy watching the customers look at our product offerings, and during the times that we engage with them, we often talk at dinner about the feedback on a certain product we brought or feeder design we engineered.

The last third is the minute the show closes. For anyone that has never been at ...

A Sneak Peek, Royal Master at IMTS 2016

If you look at the IMTS website at imts.com you will see that the show is approaching. This fact came to light the other day as we began making flights for our crew that comes out to the show. What makes us different from other companies that exhibit is we bring personnel that can actually answers questions. A response in booth6646 is not a “ here’s a brochure and someone will call you”! You will never find us sitting at a table reading a newspaper being bothered when someone walks up to ask a question.

Royal Master Grinders is at IMTS to engage with you, answer your questions and work with you to develop your projects.

IMTS has a theme of “We Are….” For 2016. If I had to add to this from the Royal Master Perspective, I would have to say that we are “engaging”. At the show we have Mechanical Engineers, Electrical Engineers and Programming Engineers on site to work with you and your project. Bring a drawing, sketch, or an idea, and leave with answers, a machine design and a proposal. Come to our booth once, or a dozen times during the week, and you will engage with our team to have your project further developed.

For this show we have a lot of new technology to demonstrate. We have Project AMO, New Feeding systems, including robotics and our TG-12×8 grinding 12 automotive parts at a time. Our GenerationX3 will be grinding Endodontic files. For those whom have spent some time in a dentist chair getting a root canals this will make stopping by a must. All of this technology will become live at www.booth6646.com in the coming weeks.

What is Project AMO? It is a development that Royal Master Grinders has engineered to take machine technology to an entire new level. Royal Master with our engineering team has always been at the forefront of this technology since we introduced lights out manufacturing in 2006. Now we have taken Smart Machine technology to a completely new level which has not been seen to date. We will be sending out more details on this as IMTS gets closer. It will be worth the wait!

Outside of IMTS, Royal Master is extremely busy and our backlog extends well into the fourth quarter of the year. We have been strong in all areas of our customer base, Medical, Automotive as ...

After 65 Years, our Core Values Stay the same

It has been a while since our last blog entry. In 2015 we have seen our TG-12×8 take a huge step forward as we have been shipping these machines regularly and we have supplied these machines to the medical, ceramic, carbide, automotive, aerospace, as well to two gauge pin companies. The gauge pin companies are finding this machine to be extremely accurate with its twin grip spindles We achieved under .000010” in roundness and are regularly holding .000015” roundness.

We are looking forward to MDM West in Anaheim California this year as we always look forward to introducing newer technology at this event. This year we are extremely excited as we have two unique projects that we are bringing to the show. If your coming, please stop by and visit. If you are not able to visit in January we will discuss on royalmaster.com what we have and what makes it so special.

We have made some additions to the Royal Master family as we have added Kristin who is the ultimate in administrative assistants. You will be meeting her when you call or visit. I guarantee she is as friendly as Lori was all of these years! After all after 65 years in business we still and always have a friendly voice answering the phones. For those who are counting, Lori is on year 30 with us and still counting, she is now in purchasing helping out there now.

We have also added Stacy who is in customer service with Alan. Alan is happy to have the help and Stacy is doing a great job as she was familiar to Royal Master before she came on board full time. Stacy has hit the ground running and Alan and Stacy have made a seamless pair when helping out our customers.

Also another Generation of Allen’s has moved into the lab as Rodney’s son is now a service man. He is enjoying the travel as Rodney and the family travelled extensively as he and his siblings were growing up.

As Sr and I think about the direction of 2016 and beyond at Royal Master we are extremely satisfied with company we have built, and enthused for what we have around the corner. However there are certain core principles that we will not alter,

• a friendly voice on the other side of the phone in all aspects of our business.

Happy Milestone Birthday to John Memmelaar Sr!

February 24th was John Sr’s birthday, a milestone birthday at that. All the employees at Royal Master celebrated with cake and a VERY loud chorus of Happy Birthday! Happy Birthday Dad

The Top 5 Questions Asked at IMTS

IMTS is over 2 months in our rear view mirror and it was one of the most satisfying experiences that Royal Master has ever had at that show. We experienced record attendance both at the show and a record number of qualified leads at our booth. With a spectacular amount of interest in our new TG-12×8 machine we have had two machines full time running experimental test grinds, and 4 machines sold since the show.

One of those test grinds is grinding 3” diameter steel bars, 12” long. We recently demonstrated it for the prospective client and they had very favorable things to say about then machine’s performance. Holding .0001” over the length of the bar while removing .003” the machine was not overmatched at all. Stay tuned for more on this application as time moves forward.

At the show we were grinding titanium on our Thrufeed microsize machine. When we came home, we have been inundated with applications that mirror this type of application as well as grinding Carbides, Ceramics as well as PCD inserts. The end user of the show machine has since taken delivery since and is reporting great grinding results.

Royal Master Grinders is also redefining something as simple as an instructional manual for the TG-12×8 machine. The machine is available with a “ manual on tablet “. Not a stone tablet, but a Microsoft tablet PC. Having all the machine’s solid models, electrical schematics as well as video manuals at a touch of a fingertip is valuable, and handy to have in this electronic version. We are proud to claim that we are the first machine tool company to provide such an opportunity for our customers.

At IMTS 2014 visitors to our booth asked a lot of great questions and for those whom could not visit us, please see our Booth6646.com site for a full tour of the booth, but to summarize, here are the top 5 questions that were asked:

1. “What did Royal Master Grinders bring that’s new this year?”

2. “Can you automate this part I want to grind ?”

3. “My Cincinnati’s are old and worn out, what do you have to replace them?”

4. “Can you hold “ this tolerance”?”

5. “How small, ( and big ) can you grind on your machines?”

6. And one for the bonus, “do your feet hurt after standing this plastic floor all day?”

Answer #1:

Royal ...

FINISHED! Ready for you on Monday!

For the last 9 months we have planned, manufactured, marketed, and executed the most aggressive IMTS plan in Royal Master history. Many of you have heard from us about our TG-12×8, our new virtual graphical package, New machine enclosure, plus various other items that we have been planning. Monday we finally welcome the first visitor to our booth. I have enjoyed this IMTS as Social Media, this blog and the advent of e-mail communication has allowed me to communicate with many of you. Over the last 4 years, this blog has been read over 6,800 times. you have met many of our longtime employees, my kids, experienced a slice of life at Royal Master, and shared some humorous trips around the world with me. Thank you for reading and if you do come to the booth this week, and you have read the blog, tell us about your favorite post.

From this

to this

IMTS Set-up Day to Day

The first week of set-up is finished and we are ready for week #2. See below for the progress we have had last week. This week Kevin and Arnold come to help get all the machines running and grinding for next week.

Our Truck is somewhere between RMG and Chicago

We loaded out on Saturday and everything went smoothly, no issues. We took up most of the flatbed trailer, with just a little to spare. We added Todd’s, Bob’s and Jesse’s bicycles as they like to ride up and down lakeshore drive in the morning before breakfast. They will have a blog during the show about that experience. They normally have good stories during breakfast about the morning ” sights”

Here are some photos from Saturday Morning:

So the plan for the rest of the week is the following:

Tuesday, fly to Chicago, Lay the flooring, get rough electrics pulled from the floor, chalk out the machine layout

Wednesday, take delivery of the machines, get the spotted, run electrics and air under the flooring

Thursday, Put booth up, hook machines up

Friday, Power up all machines, and put everything that was shipped away

Saturday, organize, and clean up the booth for Tuesday when Service engineers come to get all the machine running.

I’ll be posting update photos as we go along.

We ship on Saturday…

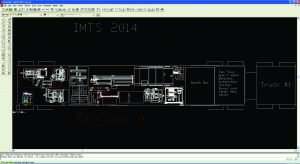

Even though IMTS is still technically 21 days away from the opening ceremony, we ship all of our equipment and support materials on Saturday. We have 16 different items packed on a 53′ flat bed and for full disclosure, this is the first time in 4 IMTS shows that I had to send an additional package to the advance warehouse. It has always been a source of personal pride that I fit a whole lot of stuff on the truck, and in past years, I have had no more than 6″ left at the back of the truck when we were all done packing it up. I had tried a multitude of combinations and at the end of the truck, there was still always one skid of stuff left over. Just not enough room.

This is a photo of last years truck:

This year, as usual I have it in AutoCAD to make sure that everything could fit, and well, it did not.

Something that you’ll never see on another centerless grinder…

Royal Master has always been on the forefront of graphical machine controls, since we introduced the Generation 4 Guide wire grinding machine back in the Early 1990’s with a windows machine control We were one of the first machine tools to offer such a package to the world. Since then we have been offering new more innovative and user friendly systems. We were the first to offer a light out system that was intelligent enough to be viewed from the couch in your living room Then we offered a machine control that e-mailed you statistics, such as up time, parts per minute, and maintenance alerts.

For IMTS 2014 we are bringing a custom designed 3D Graphical package for CNC dressing simulation. Before you ever put a diamond or diamond disk to the wheel, simulate the dress right from your Excel sheet, or watch the progress of your dress on the screen as the dressing is occurring. Rotate 360 degrees on any axis to see the shape, or watch the coupon in the lower right hand corner for a more traditional look at the dressing progress.

This graphical package is standard equipment on all machines with CNC dressing programs.